When we think of medicine, we often imagine tiny pills or bottles of syrup that help us feel better. But before these medicines reach us, there is a complex process that takes place behind the scenes. A big part of that process involves pharmaceutical impurities and intermediates. These may sound like technical terms, but they play an important role in making sure our medicines are safe and effective.

In this article, we will explore how suppliers manufacture pharmaceutical impurities and intermediates in a simple and easy-to-understand way. Whether you’re a student, a researcher, or someone working in the pharmaceutical industry, this guide will help you understand what these substances are and how they are made.

What Are Pharmaceutical Impurities and Intermediates?

Before diving into the manufacturing process, it’s important to understand what we’re talking about.

What Are Pharmaceutical Impurities?

Pharmaceutical impurities are unwanted substances that may be found in a drug product. These can appear during the manufacturing process, storage, or even due to chemical reactions over time. Impurities must be studied and controlled because they can affect the safety, quality, and effectiveness of a medicine.

There are several types of impurities:

- Organic Impurities – Formed during the production or storage of the drug

- Inorganic Impurities – From raw materials or equipment (like heavy metals)

- Residual Solvents – Leftover solvents used in making the drug

- Degradation Products – Created when the drug breaks down over time

What Are Pharmaceutical Intermediates?

Intermediates are the middle steps in the chemical process used to make the final drug. Think of them like puzzle pieces that are put together to make the complete medicine. They are not the final product but are necessary to create it.

Why Are Impurities and Intermediates Important?

You might be wondering—why do we care so much about these substances? Here’s why:

1. Safety and Quality

Impurities, if not controlled, can be harmful. That’s why drug manufacturers must know what impurities are present and keep their levels very low.

2. Regulatory Approval

Global health authorities like the FDA or EMA require companies to show data on impurities and intermediates before approving any new drug.

3. Understanding Drug Behavior

Sometimes, studying impurities and intermediates helps scientists understand how a drug behaves in the body or during storage.

Who Manufactures Pharmaceutical Impurities and Intermediates?

Not all drug companies make these substances themselves. Often, they outsource this part to specialized suppliers. These suppliers have the right tools, labs, and experience to make these complex molecules in a clean, safe, and precise way.

Some suppliers focus only on:

- Impurities for research and reference

- Intermediates for Active Pharmaceutical Ingredient (API) production

- Custom synthesis for new or rare substances

These suppliers work closely with pharmaceutical companies, research labs, and regulatory bodies.

How Do Suppliers Manufacture Pharmaceutical Impurities?

Let’s now look at the detailed steps suppliers follow to produce impurities safely and correctly.

Step 1: Understanding the Chemical Structure

The process starts by studying the chemical structure of the main drug. Scientists look for possible ways that the drug could break down or react to form impurities. They ask:

- What reactions could happen during production?

- What happens when the drug is exposed to light, heat, or air?

- What materials or solvents are used that could leave behind impurities?

Based on this information, scientists create a list of possible impurities.

Step 2: Designing the Synthesis Route

Once they know which impurity they need to make, the next step is to design a chemical pathway to produce it. This is called synthetic route design.

Chemists plan how to go from basic raw materials to the desired impurity using chemical reactions. The process must be:

- Safe – No dangerous side reactions

- Efficient – Fewer steps, less waste

- Cost-effective – Using affordable and available chemicals

- Scalable – Can be done in small labs or large batches

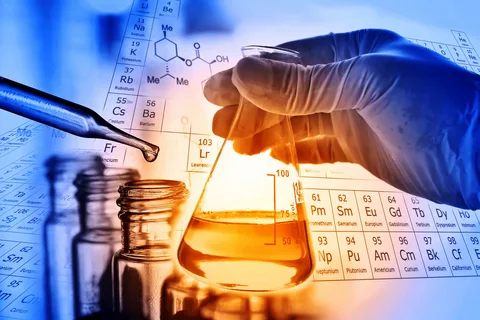

Step 3: Laboratory Synthesis

Now it’s time to make the impurity in the lab.

How This Works:

- Small batches are created in glassware using precise measurements.

- Reactions are carried out under controlled temperatures and conditions.

- Special chemicals, called reagents, are added to drive the reactions.

- The product is purified using filters, solvents, or chromatography.

This step requires great skill. Even tiny errors can lead to the wrong impurity or a product that’s not pure enough.

Step 4: Purification and Isolation

After the impurity is made, it needs to be purified. This is a crucial step because researchers and regulators need a very pure sample to study.

Common Purification Techniques:

- Crystallization – Growing pure crystals from the mixture

- Chromatography – Separating different parts using a column

- Filtration – Removing solids from liquids

- Distillation – Using heat to separate substances based on boiling points

The goal is to reach a purity level of 95% or higher.

Step 5: Characterization and Testing

Once purified, the impurity is analyzed to confirm its identity and purity.

Common Tests Include:

- HPLC (High-Performance Liquid Chromatography)

- NMR (Nuclear Magnetic Resonance)

- Mass Spectrometry (MS)

- Infrared Spectroscopy (IR)

This helps prove that the product is correct and suitable for research or regulatory submission.

Step 6: Packaging and Documentation

After testing, the impurity is carefully packaged in small vials or containers. Along with the product, the supplier provides:

- Certificate of Analysis (COA) – Shows test results

- Material Safety Data Sheet (MSDS) – Safety information

- Labeling with chemical name, CAS number, purity, etc.

The impurity is then shipped to customers—usually pharmaceutical companies or research labs.

How Do Suppliers Manufacture Pharmaceutical Intermediates?

Making intermediates is a little different from making impurities. Intermediates are needed in much larger quantities and must be produced under stricter quality control.

Step 1: Process Development

Suppliers work with pharmaceutical clients to develop a reliable process for making the intermediate.

They study:

- Best raw materials to use

- Chemical reaction steps

- Equipment needed

- Time, temperature, and pressure requirements

This planning stage is often done with the help of process chemists and chemical engineers.

Step 2: Large-Scale Production

Unlike impurities (which are made in small amounts), intermediates are made in bulk.

Production Takes Place in:

- Pilot plants – For mid-sized batches

- Manufacturing facilities – For large-scale production

Reactions are carried out in large reactors with full safety systems. Every step is carefully monitored to maintain consistency and quality.

Step 3: Quality Control and Compliance

Intermediate manufacturers must follow Good Manufacturing Practices (GMP) to ensure product safety and traceability.

They perform:

- In-process testing – To catch problems early

- Final product testing – To confirm quality

- Batch documentation – Full records of production

If an intermediate doesn’t pass testing, it’s rejected or reprocessed.

Step 4: Delivery and Customer Support

Once approved, intermediates are packed and shipped in secure containers. The supplier also provides:

- Product samples for testing

- Support for regulatory audits

- Custom packaging if needed

Some suppliers also offer custom synthesis services if the client needs a special or new intermediate.

Final Thoughts

Pharmaceutical impurities and intermediates may not get much attention, but they are essential to the world of medicine. The suppliers who make them play a critical role in ensuring that drugs are safe, effective, and approved by regulators.

From designing the chemical process to delivering a high-purity product, the entire journey requires expertise, quality control, and a commitment to safety.

If you’re working in the pharmaceutical field or simply curious about how medicines are made, knowing about these key steps can help you appreciate the hard work behind every dose of medicine.

For more insightful articles related to this topic, feel free to visit: penwhatmatters