In today’s fast-paced industrial world, conveyor belts are the backbone of countless operations. From manufacturing plants to warehouses and mining facilities, these systems keep goods moving efficiently. However, like any machinery, conveyor belts are prone to wear and tear. When damage occurs, businesses face a critical decision: attempt a quick fix or invest in professional repair services. For reliable, long-lasting solutions, Oliver Rubber stands out as a trusted name in Conveyor Belt Repair. This blog explores why expert repair services are essential and how Oliver Rubber delivers top-notch results.

Why Conveyor Belts Need Professional Attention

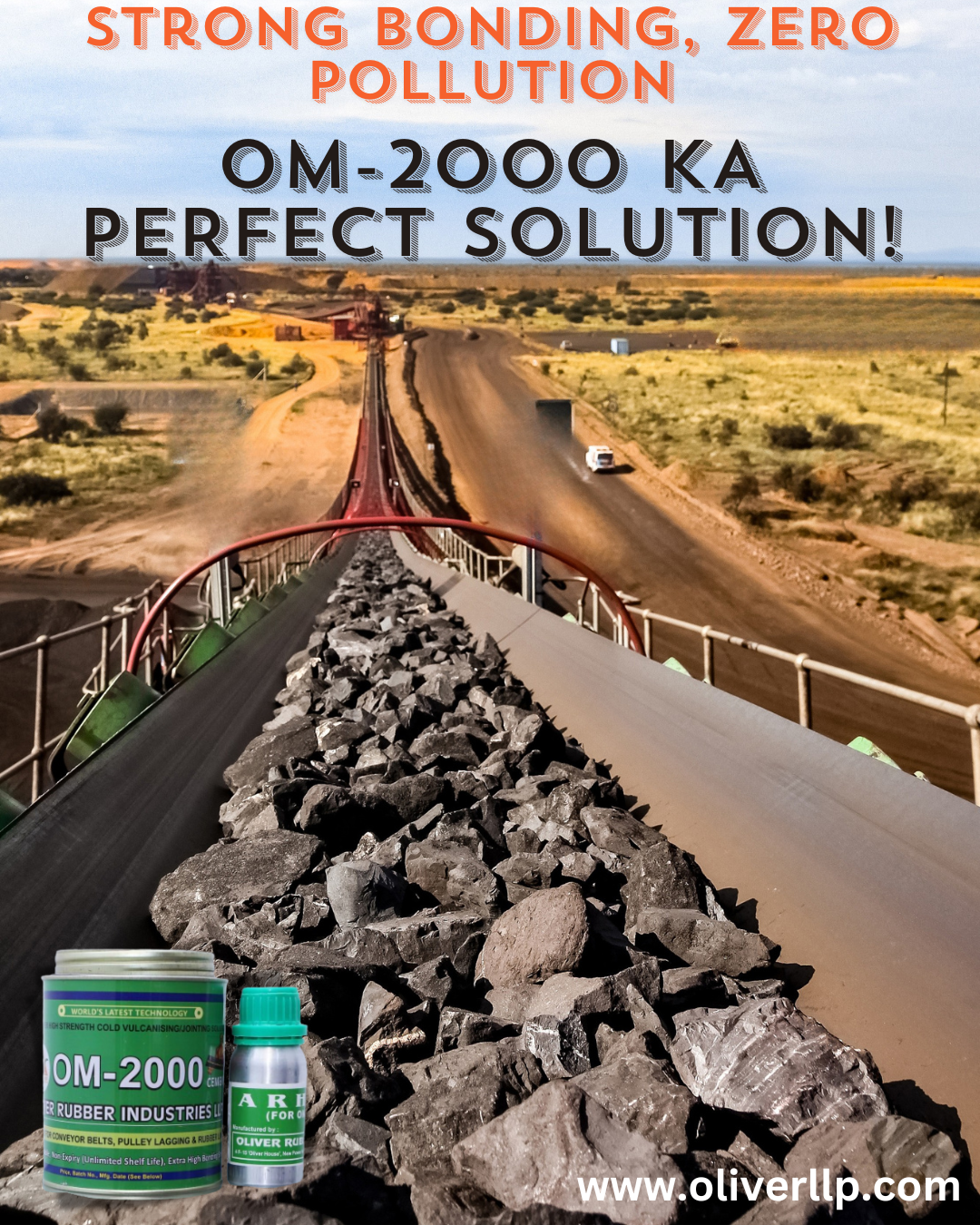

Conveyor belts endure constant stress—whether it’s from heavy loads, abrasive materials, or continuous operation. Over time, this leads to issues like tears, fraying, misalignment, or even complete breakdowns. While some minor damages might seem manageable with DIY methods, such fixes are often temporary and can worsen the problem. A poorly repaired belt risks downtime, safety hazards, and costly replacements.

Professional repair services, like those offered by Oliver Rubber, address these challenges head-on. With years of expertise and specialized tools, their team ensures that repairs not only fix the immediate issue but also enhance the belt’s longevity. This proactive approach saves businesses time and money while maintaining operational efficiency.

Oliver Rubber: A Leader in Conveyor Belt Solutions

Oliver Rubber has built a reputation for excellence in the conveyor belt repair industry. Their services cater to a wide range of sectors, including agriculture, mining, and logistics. What sets them apart is their commitment to quality, precision, and customer satisfaction. By using advanced techniques and high-grade materials, Oliver Rubber ensures that every repair meets industry standards.

One key advantage of choosing Oliver Rubber is their tailored approach. No two conveyor systems are identical, and their team understands this. They assess each belt’s unique condition—considering factors like material type, damage extent, and operational demands—before crafting a customized repair plan. This attention to detail minimizes the risk of recurring issues and maximizes uptime.

Common Conveyor Belt Problems and Solutions

Understanding the typical issues conveyor belts face can highlight why expert intervention is crucial. Here are some common problems and how Oliver Rubber tackles them:

- Tears and Cuts: Sharp objects or excessive load pressure can rip conveyor belts. Oliver Rubber employs vulcanization techniques or cold bonding, depending on the damage, to seamlessly mend tears while restoring strength.

- Belt Misalignment: When belts drift off course, they wear unevenly and strain the system. Oliver Rubber’s technicians realign belts and adjust tracking components to prevent further damage.

- Surface Wear: Abrasion from rough materials erodes belt surfaces over time. Oliver Rubber applies durable patching materials or protective coatings to extend the belt’s life.

- Joint Failures: Weak or improperly installed splices can fail under tension. Using state-of-the-art splicing methods, Oliver Rubber ensures joints are as strong as the original belt.

These solutions require skill and precision—qualities that Oliver Rubber brings to every project.

Benefits of Choosing Oliver Rubber for Conveyor Belt Repair

Opting for Oliver Rubber’s Conveyor Belt Repair services offers numerous advantages. First, their rapid response reduces downtime, keeping your operations on track. Second, their repairs are cost-effective, preventing the need for premature belt replacements. Third, their focus on safety ensures that repaired belts meet regulatory standards, protecting both workers and equipment.

Additionally, Oliver Rubber emphasizes sustainability. By repairing belts instead of discarding them, they help businesses reduce waste and lower their environmental footprint. This eco-conscious approach aligns with modern industrial goals of efficiency and responsibility.

Preventive Maintenance: The Key to Longevity

Beyond repairs, Oliver Rubber advocates for regular maintenance to prevent major issues. Scheduled inspections can catch small problems—like minor wear or loose components—before they escalate. Their team provides maintenance plans tailored to your conveyor system, ensuring optimal performance year-round. This proactive strategy complements their repair services, offering a holistic solution for conveyor belt care.

Why DIY Repairs Fall Short

Some businesses attempt in-house repairs to save costs, but this often backfires. Without proper tools, materials, or training, DIY fixes can weaken the belt further or introduce new vulnerabilities. For instance, using the wrong adhesive or patching technique might lead to delamination under stress. Oliver Rubber eliminates these risks by leveraging industry-grade products and certified technicians.

Trust Oliver Rubber for Your Conveyor Needs

When conveyor belts falter, the ripple effect on productivity can be significant. That’s why partnering with a reliable service provider like Oliver Rubber is a smart investment. Their expertise in Conveyor Belt Repair ensures that your systems run smoothly, safely, and efficiently. Whether you’re dealing with an urgent breakdown or seeking long-term maintenance, Oliver Rubber delivers solutions you can count on.

In conclusion, conveyor belt repair isn’t just about fixing damage—it’s about preserving the heart of your operations. Oliver Rubber’s dedication to quality craftsmanship, innovative techniques, and customer-focused service makes them a standout choice. Don’t let conveyor issues slow you down; trust Oliver Rubber to keep your business moving forward. Visit their website today to learn more about how they can support your conveyor belt needs.