Introduction

Sustainability is no longer just a corporate buzzword; it has become an essential strategy for businesses aiming to reduce environmental impact while optimizing operational efficiency. One of the most effective ways for companies to minimize their carbon footprint is by adopting efficient waste management solutions such as vertical baling press machines. These machines play a crucial role in compacting recyclable materials, reducing landfill waste, and lowering carbon emissions associated with waste transportation and disposal.

This article explores how businesses can leverage vertical balers to achieve sustainability goals, the environmental benefits of using a vertical baling press, and practical ways to integrate these machines into existing waste management systems.

Understanding the Carbon Footprint of Waste Management

Waste generation contributes significantly to greenhouse gas (GHG) emissions. Improper disposal of materials, excessive transportation of waste, and inefficient recycling processes lead to increased carbon dioxide (CO2) and methane (CH4) emissions. Businesses that fail to manage waste efficiently not only contribute to pollution but also miss opportunities for cost savings and compliance with environmental regulations.

The key contributors to carbon emissions in waste management include:

- Landfills: Decomposing waste in landfills emits methane, a potent greenhouse gas.

- Transportation: Moving unprocessed waste to disposal sites increases fuel consumption and emissions.

- Inefficient Recycling: Poor waste sorting and handling result in higher energy consumption during recycling.

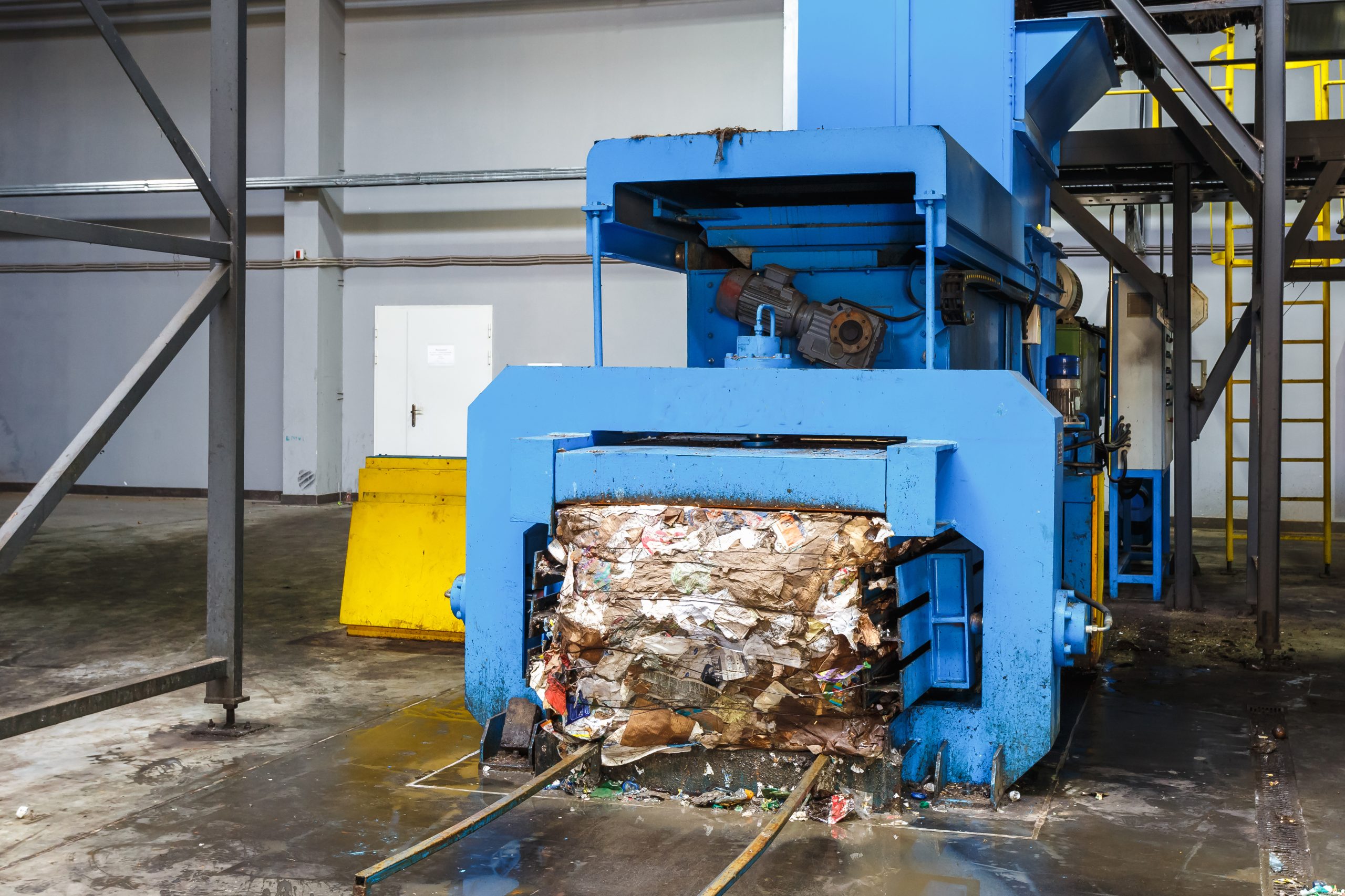

A vertical baling press addresses these challenges by streamlining waste processing, making recycling more efficient, and reducing the number of waste disposal trips required.

How Vertical Balers Reduce Carbon Footprint

1. Minimizing Landfill Contributions

One of the most significant advantages of vertical balers is their ability to compress waste materials into compact, manageable bales. By reducing the volume of waste, businesses can increase the efficiency of recycling programs and decrease landfill dependency. Since recyclables are separated and compressed effectively, they are more likely to be reused in the production cycle rather than ending up in landfills.

For instance, industries generating large volumes of cardboard, plastics, or textiles can use a vertical baling press to create dense bales that can be directly sent to recycling plants. This process reduces methane emissions from landfill decomposition and supports the circular economy.

2. Reducing Waste Transportation Emissions

Loose waste takes up more space, requiring more frequent transportation to disposal sites. This increases fuel consumption and carbon emissions from waste-hauling vehicles. Vertical balers significantly reduce waste volume, meaning fewer trips are needed to transport the same amount of recyclable materials.

For example, a business producing high volumes of paper and packaging waste can use a vertical baler to compress materials into bales, reducing truckloads required for disposal. This simple yet effective step cuts down on CO2 emissions and transportation costs.

3. Enhancing Recycling Efficiency

Effective recycling requires waste to be sorted and processed efficiently. Many recyclable materials, such as paper, plastic, and aluminum, lose their recycling potential when mixed with general waste. A vertical baling press helps businesses separate materials at the source and compress them into uniform bales, ensuring they can be easily transported to recycling facilities with minimal processing.

Furthermore, compressed bales take up less storage space, allowing businesses to accumulate more recyclables before dispatching them for processing. This reduces the frequency of recycling pick-ups and energy consumption associated with transportation.

4. Reducing Energy Consumption in Waste Handling

Traditional waste disposal and handling methods often involve excessive manual labor, energy use, and inefficient sorting processes. Vertical balers automate and streamline these processes, reducing the overall energy footprint of waste management operations.

For instance, many vertical baling press models feature energy-efficient hydraulic systems that require less power to operate compared to alternative waste compression methods. This means businesses can lower electricity consumption while achieving better waste management results.

Industries Benefiting from Vertical Balers

Retail and E-Commerce

Retailers generate substantial volumes of cardboard, plastic wrap, and packaging materials. A vertical baler allows them to compress waste efficiently, reducing disposal costs and improving sustainability efforts.

Manufacturing and Industrial Sectors

Factories dealing with metal scraps, textiles, or paper waste can use vertical balers to optimize recycling and minimize storage space requirements. This reduces operational costs and enhances waste management strategies.

Hospitality and Food Services

Restaurants, hotels, and catering services produce high volumes of packaging waste and organic materials. Using a vertical baling press ensures recyclables like plastic bottles and aluminum cans are efficiently processed, reducing waste disposal expenses.

Healthcare and Pharmaceuticals

Medical institutions handle large amounts of packaging waste from medication supplies. Vertical balers help in segregating and compacting recyclable materials, supporting eco-friendly waste disposal practices.

Steps to Implement Vertical Balers for Sustainability

1. Conduct a Waste Audit

Before investing in a vertical baler, businesses should analyze their waste generation patterns. Identify the most common types of recyclable materials and assess how a vertical baling press can optimize waste management.

2. Choose the Right Vertical Baler

There are different models of vertical balers tailored to specific waste types and business sizes. Key factors to consider include:

- Material Type: Cardboard, plastic, textiles, or metals.

- Bale Size and Weight: Depending on storage and transportation needs.

- Operational Efficiency: Energy consumption and ease of use.

3. Train Staff on Waste Handling

Proper training ensures that employees understand how to use vertical balers effectively, maximizing waste compression efficiency and maintaining safety standards.

4. Partner with Recycling Facilities

Establish partnerships with recycling centers that accept baled materials. This guarantees a streamlined process from waste compression to recycling, ensuring environmental benefits.

5. Monitor and Optimize Waste Management Practices

Regularly review waste management practices and measure the impact of vertical baling on carbon footprint reduction. Businesses should aim for continuous improvements to enhance sustainability efforts.

Conclusion

Investing in a vertical baling press is a smart and sustainable choice for businesses looking to reduce their carbon footprint. By optimizing waste compression, minimizing landfill contributions, and enhancing recycling efficiency, vertical balers play a vital role in modern eco-friendly waste management strategies.

Companies across various industries can benefit from adopting these machines, not only to meet environmental regulations but also to cut costs and improve operational efficiency. As businesses move toward a more sustainable future, integrating vertical balers into waste management systems is a step in the right direction.